A Revolutionary Heater

In 1954, Watlow's FIREROD® cartridge heater was patented with the ability to provide superior heat transfer, uniform temperatures, and resistance to oxidation and corrosion throughout demanding high-temperature applications. This is accomplished with Watlow's swaging method, increasing thermal conductivity and providing faster and more even heating. Swaging ensures even, efficient distribution of heat to the sheath contributing to prolonged heater life and lower energy consumption.

FIREROD® Features & Benefits

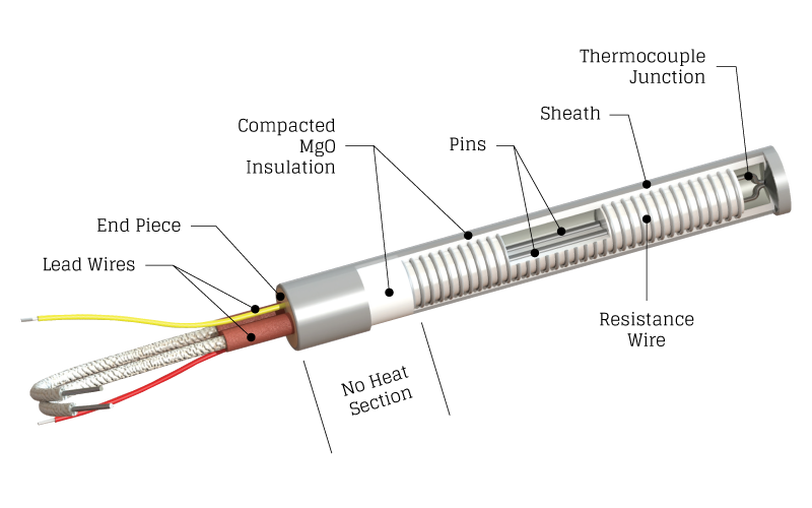

Nickel-chromium resistance wire

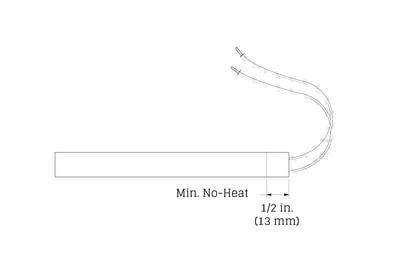

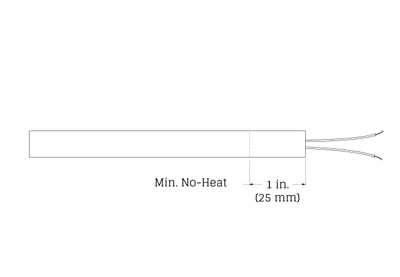

Ensures even and efficient distribution of heat to the sheath. Conductor pins Provide a metallurgical bond to the resistance wire. Ensure a trouble-free electrical connection. Magnesium oxide insulation of specific grain and purity Results in high dielectric strength and contributes to faster heat-up. Alloy 800 sheath Resists oxidation and corrosion from heat, many chemicals and atmospheres. Minimal spacing between the element wire and sheath Results in lower internal temperature. Accommodates a design with fewer or smaller heaters operating at higher watt densities. International Organization for Standardization (ISO) 9001 certified Provides confidence that quality and reliability expectations are met. UL® and CSA approved flexible stranded wires Lead insulation rated to temperatures up to 480°F (250°C). Patented lead adapter (LA) method Allows same day shipment on more than 150,000 configurations of stock FIREROD® heaters and lead. |

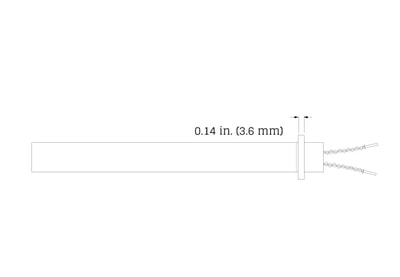

FIREROD® Assembly

Typical Applications

- Semiconductor chamber heating

- Semiconductor wire and die bonding

- Freeze protection and deicing of equipment in cold climates or applications

- Humidity control

- Patient comfort heating used in medical devices

- Mold die and platen heating

- Seal bars used in packaging equipment

- Test sample heating in gas chromatography equipment

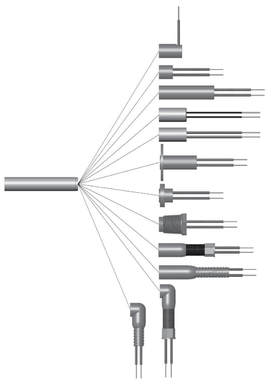

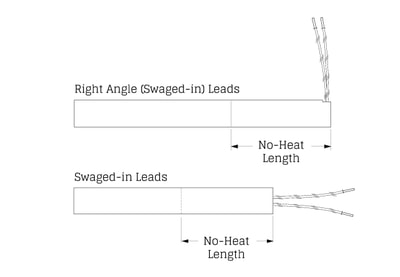

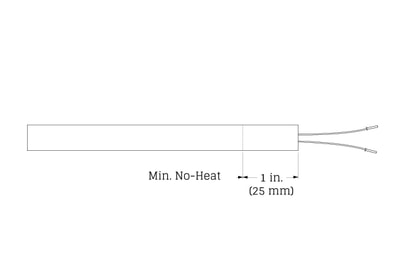

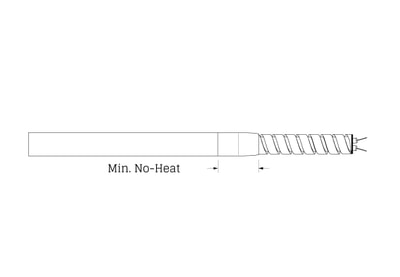

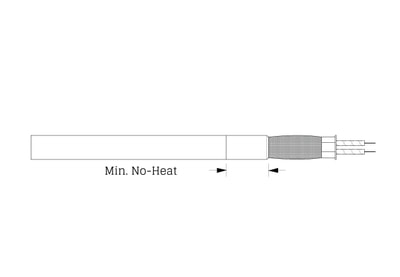

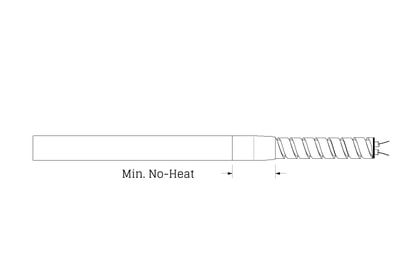

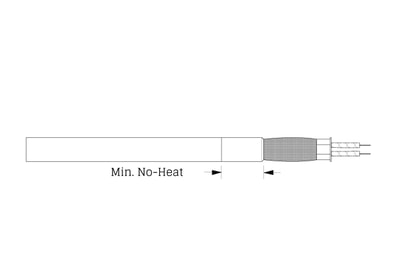

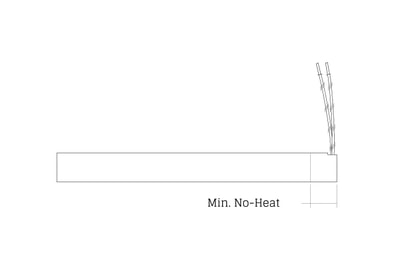

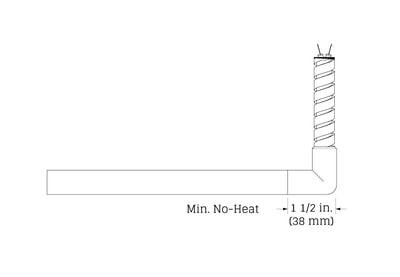

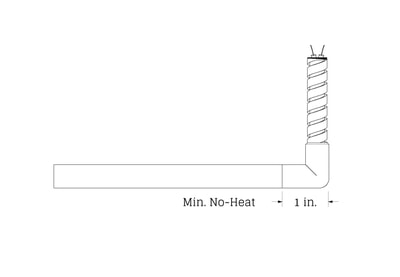

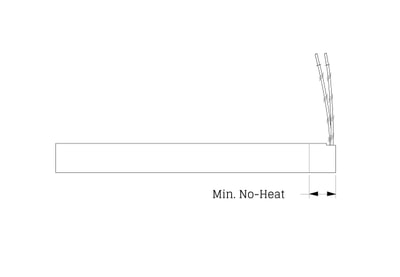

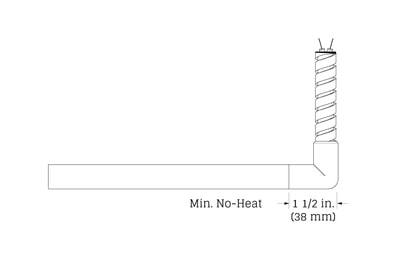

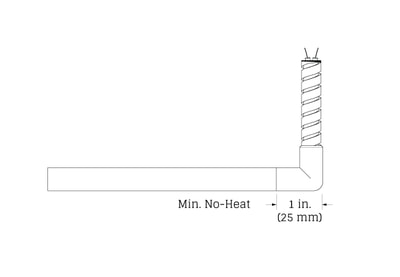

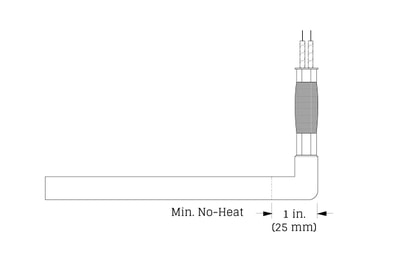

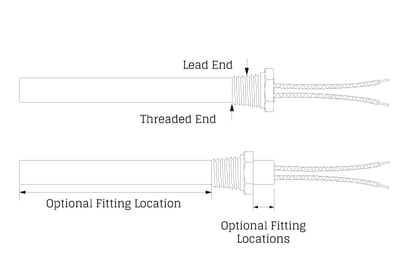

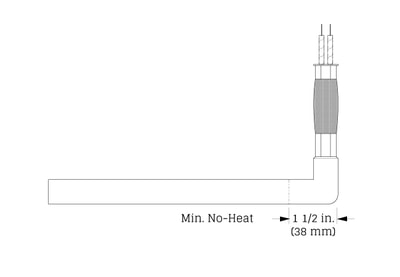

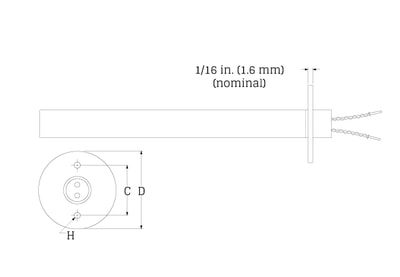

Watlow's Patented LA (Lead Adapter) Modification Method

Watlow's LA process allows the base FIREROD® heater to be modified into a multitude of configurations to meet highly specific needs. The base heater can then be customized by adding various finishing options, such as lead length, lead protection, flanges, locating rings, and right-angle constructions.

|

Other Watlow Electric Heaters

|

Watlow Air Heaters

Watlow has developed a line of process air heaters that offer performance and versatility in medium to low temperature applications. This rugged and reliable line of industrial heaters efficiently conducts heat. |

|

Watlow Cartridge & Insertion Heaters

Watlow designed and manufactured the first swaged cartridge heater and revolutionized the heating element industry. With premium materials and tight manufacturing controls, Watlow's cartridge heaters (insertion heaters) provide superior heat transfer, uniform temperatures, resistance to oxidation and corrosion and long life even at high temperatures. |

|

Watlow Tubular Heaters

Single- and double-ended tubular heaters lend themselves to virtually the entire range of immersion and air heating applications. They have a variety of mounting and termination options that make them ideal for industrial applications. Watlow® tubular heaters are UL® and CSA component recognized up to 240V. |

|

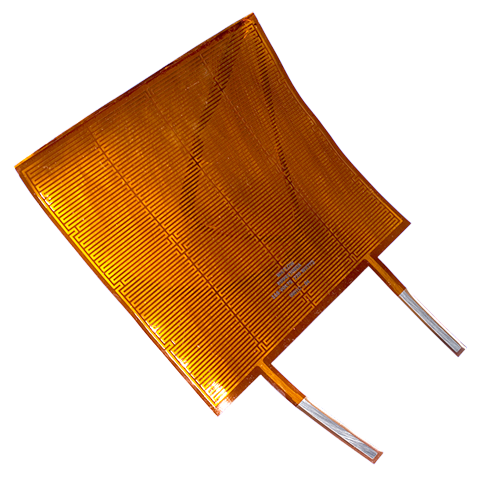

Watlow Flexible Heaters

Flexible heaters from Watlow are thin, bendable and shaped to fit almost any type of equipment. Heat can be applied to the most complex shapes, geometries, curves and pipes conceivable without sacrificing efficiency or dependability. |

|

Watlow Immersion Heaters

Watlow's immersion heaters are designed primarily for direct immersion in liquids such as water, oils, solvents and process solutions, molten materials as well as air and gases. By generating all the heat within the liquid or process, these heaters are virtually 100 percent energy efficient. |

|

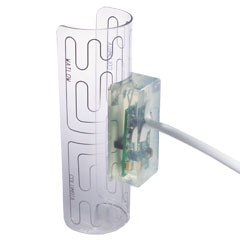

Watlow Circulation Heaters

Watlow's circulation heaters are compact heating systems for fluids and gases. These heaters are ideal for applications such as purified and inert gases, supercritical fluids and liquids like de-ionized water for use in semiconductor and electronics industries as well as for general liquid and gas heating applications. |

|

Watlow Fluid Delivery Heaters

Watlow's syringe heater was developed for the needs of medical injection applications. The special design provides a heated fluid and drug delivery system solution with long operational life which improves system reliability while reducing equipment down time. |

|

Watlow High-Temperature Heaters

Watlow's MULTICELL™, FIREROD®, tubular, and ceramic fiber heaters offer capabilities such as ultra-fast ramp rates, precise temperature uniformity and high temperatures for applications requiring low thermal mass. |

|

Watlow Strip Heaters

Watlow's strip/clamp-on heaters are a versatile solution for a number of applications. They can be bolted or clamped to a solid surface for freeze and moisture protection, food warming and other applications. These heaters make use of the most advanced heat construction techniques. |

|

Watlow Nozzle Heaters

Watlow offers a full line of hot runner nozzle heaters for the plastics industry as well as slip-on heaters for the medical and analytical industries. While every heater has a unique set of capabilities, each nozzle heater is designed to meet specific application requirements. |

|

Watlow RAYMAX® Panel Heaters

Watlow's diverse radiant heater line provides a solution for almost any application requiring radiant heat. Watlow's capabilities cover a wide range of needs, from contamination-resistant panel heaters to rugged tubular elements and high temperature ceramic panels. |

|

Watlow Mineral Insulated (MI) Band Heaters

The MI band heater from Watlow® is a high-performance heater. The band heater's performance and name are derived from Watlow's exclusive mineral insulation—a material with much higher thermal conductivity than mica and hard ceramic insulators used in conventional heaters. |

Proheat is a proud distributor of all Watlow heater products, including band heaters, cartridge heaters, strip heaters, tubular heaters, immersion heaters, and more. We are dedicated to provide excellence in distribution.