Knowing which cartridge heater to use in order to maximize your efficiency can be difficult. Heater life, start up time, process temperatures, durability, size, and cost all play an important role. While reviewing our guidelines on which strip heater to choose for you particular needs, keep in mind that every application will have its own set of unique challenges.

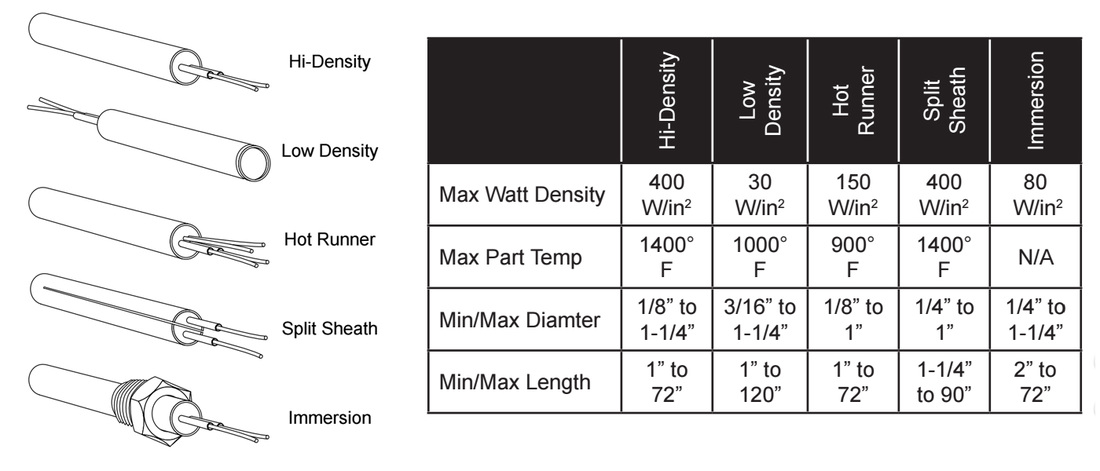

Hi-Density Cartridge HeatersHi-density cartridge heaters are the workhorse of the industry. They are good for high temperature applications and are readily available from stock in many sizes and many voltage/wattage combinations. The compacted or “swaged” MgO insulation allows for high watt densities. |

Low Density Cartridge HeatersLow density cartridge heaters are good for low to mid temperature applications and are less costly than hi-density. The construction style of a low density cartridge heater required very low watt densities, however they do have the largest length capacity. |

Hot Runner Cartridge HeatersHot runner cartridge heaters are hi-density heaters with an internal thermocouple (generally type J or K). The thermocouple can be placed at the lead end, disc end, in the middle, or attached to the sheath. |

Split Sheath Cartridge HeatersSplit sheath cartridge heaters are split down the middle. The design allows for expansion into the bore providing better heat transfer. They are warranted removable. They are good for high temperature, high watt density applications. They have longer lead time then hi or low density heaters. |

Immersion Cartridge HeatersImmersion cartridge heaters are hi-density heaters with an NPT fitting brazed to the sheath and are good for small tank heating applications. They work well for lower temperature and lower watt density applications where a standard immersion heater will not fit. |

Proheat offers a variety of industrial heating products, including band heaters, cartridge heaters, strip heaters, tubular heaters, immersion heaters, and more. We are dedicated to providing excellence in distribution.