Watt-Flex Cartridge Heaters Last Longer

Cartridge heater life is directly related to its internal operating temperature.

Watt-Flex cartridge heaters run substantially cooler and have a more uniform temperature profile than conventional heaters. The result is Watt-Flex heaters that last up to 5 times longer, have less downtime and lower operating costs than conventional cartridge heaters.

Watt-Flex cartridge heaters run substantially cooler and have a more uniform temperature profile than conventional heaters. The result is Watt-Flex heaters that last up to 5 times longer, have less downtime and lower operating costs than conventional cartridge heaters.

Efficient Heat Transfer

The high purity MgO dielectric in Watt-Flex heaters is compacted to extreme density, ensuring maximum heat transfer away from the core to the heater sheath.

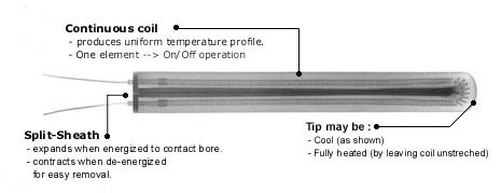

As the energized split-sheath expands, it creates intimate contact with the bore wall, efficiently transferring heater sheath to the host metal.

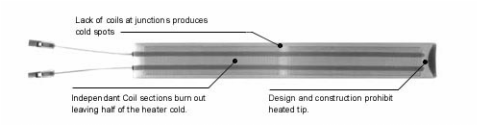

Conventional ceramic core cartridge heaters (shown below) use multiple heating cores that can independently burn out, causing a cold section on the sheath. And voids of coil at core junctions produce cold sections on the heater profile.

As the energized split-sheath expands, it creates intimate contact with the bore wall, efficiently transferring heater sheath to the host metal.

Conventional ceramic core cartridge heaters (shown below) use multiple heating cores that can independently burn out, causing a cold section on the sheath. And voids of coil at core junctions produce cold sections on the heater profile.

Unlike conventional ceramic heaters, Watt-Flex heaters use a continuous heating coil to achieve a more uniform temperature profile. With Watt-Flex heaters, there are no independent heating element sections to burn out. Watt-Flex heaters are either totally on or totally off.

Watt-Flex Cartridge Heaters Eliminate Bore Seizure

The patented split-sheath design of the Watt-Flex cartridge heater reduces your heater change-out costs by preventing heater bore seizure.

What Causes Conventional Heaters to Warp and Bind?

How the Watt-Flex Split-Sheath Prevents Bore Seizure

Watt-Flex Temperature Profiles

Unlike conventional cartridge heaters, Watt-Flex heaters use a continuous heating coil that allows for a more uniform temperature profile.

By varying the watt-density, Watt-Flex heaters can also be configured for customized temperature profiles with varying zones of heat along the heater.

The unique bi-lateral expansion of Watt-Flex cartridge heaters eliminates the need for tight fits and makes them well-suited for use in oversized bores where conventional cartridge heaters cannot be used effectively.

Cartridge heater fit is measured as the difference between the inside diameter (I.D.) of the bore and the outside dimension (O.D.) of the heater.

The suggested fit for a Watt-Flex Cartridge Heater is .007" greater than the nominal Watt-Flex heater sheath diameter.

By varying the watt-density, Watt-Flex heaters can also be configured for customized temperature profiles with varying zones of heat along the heater.

The unique bi-lateral expansion of Watt-Flex cartridge heaters eliminates the need for tight fits and makes them well-suited for use in oversized bores where conventional cartridge heaters cannot be used effectively.

Cartridge heater fit is measured as the difference between the inside diameter (I.D.) of the bore and the outside dimension (O.D.) of the heater.

The suggested fit for a Watt-Flex Cartridge Heater is .007" greater than the nominal Watt-Flex heater sheath diameter.

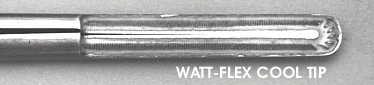

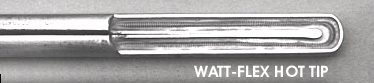

Watt-Flex Heaters: Hot Tip or Cool Tip Options

Watt-Flex heaters, however, can be constructed for hot or cool tips by either concentrating or stretching the continuous coil inside the densely compacted MgO dielectric

External Thermocouples: An Exclusive Watt-Flex Option

Watt-Flex split-sheath cartridge heaters can be manufactured with a groove along the exterior of the cartridge to accommodate a needle-type thermocouple for more accurate temperature sensing and control.

Measure temperature at the precise point of heat transfer.

Unlike conventional heaters with internal thermocouples that measure internal heater coil temperature, Watt-Flex external thermocouples measure more precisely at the point where heat transfers from the heater to the host metal.

Monitor temperature at any point along the heater.

Dalton Watt-Flex heaters give you the flexibility to monitor heat at any point along the heater, instead of at pre-defined fixed points with internal monitors in conventional heaters.

Replace heater or thermocouple independently.

With Watt-Flex external thermocouples, you can replace either the heater or the thermocouple independently, without having to replace an operational component as with conventional heater designs.

Thermocouple Specifications

Maximum Length

Thermocouples

Needle Diameters

- 15" maximum for grooved heaters with 1/4" or 3/8" diameter heaters.

- 7" maximum for grooved heaters with 1/2" diameter heaters.

- Longer heaters using 1/2" diameter or larger heaters, can be center- grooved between the legs to any depth between 6" to 15".

Thermocouples

- Type J with 48" leads.

- Type K with 48" leads.

Needle Diameters

- 0.040" for 1/4" diameter heaters and all center grooves.

- 0.062" for side-grooved 3/8" and 1/2" diameter heaters.

Lead Modifications

Standard Temperature Leads

GT insulation (teflon tape primary, glass servings, woven glass braid, teflon coated) over stranded Grade "A" nickel wire.

(< 480o F / 250o C).

Standard Temperature Teflon Leads

Extruded PFA over stranded Grade "A" nickel wire. (< 480o F / 250o C)

High Temperature Leads

Fiberglass insulation (threaded glass servings primary, treated glass braid) over stranded Grade "A" nickel wire. (< 840o F / 450o C).

Quick Disconnect

A modular plug or terminal junction in the wire for ease of heater disconnection.

Integral Ground Wire

Attached to the heater, meant for termination to ground on the machine.

Extra Length Leads

Available in any length. For wires longer than 10 feet (3 meters), a quick connect or male/female connector plug assembly can be used to reduce heater cost.

Ceramic Potting

Provides good contaminant protection, but is not a complete moisture barrier. Ceramic material supports very high temperature process heating and is rated to 2000+ oF / 1090 oC.

Mounting Bracket

An "L" shaped bracket welded to the sheath to act as an insertion stop or for mechanically securing the heater at the edge of the heat sink.

Puller End Plug

Used for heater extraction in applications where the terminal end of the heater is not accessible. Interior thread attaches the puller plug to the heater tip.

NPT Fitting

Used with Watt-Flex replaceable immersion heaters for heating liquids in vats or tanks.

Extra Cold Section at End

When the heater extends out of the bore (through insulation, for example) an extra cold section added to the cartridge heater ensures that the heated section is fully enclosed by the heat sink. The cold terminal end is usually produced by adding a longer terminal pin so no heat is produced. Longer cold sections are created by stretching the continuous coil resistance wire to limited heat production.

Ceramic Bead Insulation

Placed over insulated lead wire to protect beyond temperature rating of insulation. Withstands temperatures to 2000° F / 1090 °C.

Distributed Wattage

Watt-Flex heaters can be designed with zones of varying watt density, allowing you to put a specific amount of heat exactly where you need it.

GT insulation (teflon tape primary, glass servings, woven glass braid, teflon coated) over stranded Grade "A" nickel wire.

(< 480o F / 250o C).

Standard Temperature Teflon Leads

Extruded PFA over stranded Grade "A" nickel wire. (< 480o F / 250o C)

High Temperature Leads

Fiberglass insulation (threaded glass servings primary, treated glass braid) over stranded Grade "A" nickel wire. (< 840o F / 450o C).

Quick Disconnect

A modular plug or terminal junction in the wire for ease of heater disconnection.

Integral Ground Wire

Attached to the heater, meant for termination to ground on the machine.

Extra Length Leads

Available in any length. For wires longer than 10 feet (3 meters), a quick connect or male/female connector plug assembly can be used to reduce heater cost.

Ceramic Potting

Provides good contaminant protection, but is not a complete moisture barrier. Ceramic material supports very high temperature process heating and is rated to 2000+ oF / 1090 oC.

Mounting Bracket

An "L" shaped bracket welded to the sheath to act as an insertion stop or for mechanically securing the heater at the edge of the heat sink.

Puller End Plug

Used for heater extraction in applications where the terminal end of the heater is not accessible. Interior thread attaches the puller plug to the heater tip.

NPT Fitting

Used with Watt-Flex replaceable immersion heaters for heating liquids in vats or tanks.

Extra Cold Section at End

When the heater extends out of the bore (through insulation, for example) an extra cold section added to the cartridge heater ensures that the heated section is fully enclosed by the heat sink. The cold terminal end is usually produced by adding a longer terminal pin so no heat is produced. Longer cold sections are created by stretching the continuous coil resistance wire to limited heat production.

Ceramic Bead Insulation

Placed over insulated lead wire to protect beyond temperature rating of insulation. Withstands temperatures to 2000° F / 1090 °C.

Distributed Wattage

Watt-Flex heaters can be designed with zones of varying watt density, allowing you to put a specific amount of heat exactly where you need it.

ProductsHeaters Sensors Temp. Controls Controls & Relays Hot Runners Heat Trace Cold Weather Wire Accessories Insulation Pressure Relief Slide Products |

ServicesCredit Application Order Tracking Delivery Programs Stocking Programs R.M.A. Request Catalog Request Custom Quick |

CompanyAbout Testimonials Legal & Copyright Blog |

SupportContact Account Managers FAQ Technical Information Instructional Videos Helpful Links Downloads Line Card |

Popular ProductsChromalox Heaters Watlow Heaters Watlow EZ-ZONE® Watlow F4T MDI Hot RunnerProheat is an authorized distributor of Chromalox and Watlow heater products. Band Heaters Cartridge Heaters Strip Heaters Tubular Heaters Immersion Heaters Hot Runner Nozzles Hot Runner Systems Hot Runner Controllers |

© Proheat, Inc.