A hot runner system produces plastic molds through a process known as injection molding. The nozzle of a hot runner system is the interface between the cavity and melt delivery system and is used to feed the molten plastic into the cavity of the mold.

Different Types of Hot Runner Nozzles

Proheat is a distributor of MDI (Melt Design, Inc.) hot runner nozzles. They design and manufacture a variety of failure-resistant nozzles, including Direct Gate Nozzles, Valve Nozzles, Edge Gate Nozzles, Cluster/Multi-Gate Nozzles, and Machine Nozzles.

|

Direct Gate Nozzles

The Direct Gate Nozzle specializes in preventing nozzle leakage using H-13 steel. Its single-piece design eliminates stresses and leakage that can occur with multi-piece designs. This type of hot runner nozzle is often used in applications producing caps/closures and consumer electronic molds.

|

|

Valve Nozzles

The Power Point® Valve Gate Nozzle is internally heated, providing a uniform heat profile and offering a flow of plastic into the cavity. This eliminates blemishes that can occur with uncontrolled plastic flow. This type of hot runner nozzle is often used in medical applications where precise parts are required.

|

|

Edge Gate Nozzles

The Power Point® Edge Gate Nozzle is designed for high-volume production and caters to resins where the gate is on a sidewall, allowing you to directly gate on the side of the part. This eliminates the need for cold runners. This type of hot runner nozzle is often used in the production of medical and thin wall packaging molds, including syringes, pipettes, and hygiene products.

|

|

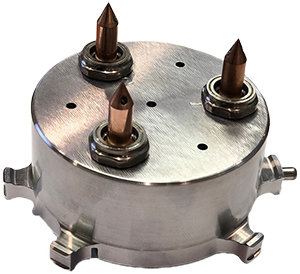

Cluster/Multi-Gate Nozzles

The Cluster/Multi-Tip Nozzle includes multiple tips, and its compact size is ideal for the production of complex, small sparts that require multiple gates in confined areas. As with the Direct Gate Nozzle, the Cluster/Multi-Gate Nozzle is often used in the product of medical and caps/closure applications.

|

|

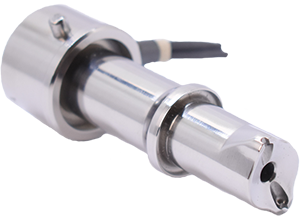

Machine Nozzles

The Equatemp® Molding Machine Nozzle is a patented design that provides high-performance, precise temperature control, and burn-out resistance. The use of ceramic-insulated resistance wire ensures the highest possible heat transfer rate. This results in a longer heater service life. The nozzle body utilizes H-13 tool steel for maximum durability.

|

Proheat is an authorized distributor of all MDI (Melt Design, Inc.) Hot Runner System, Hot Runner Nozzles, and Hot Runner Temperature Controllers. For more information or to request a quote, contact Proheat today.