With summer time in full swing (finally), you may have noticed heater failure upon start up. So this month’s Tech Tip covers the most common type of summertime heater failure: electric insulator malfunction.

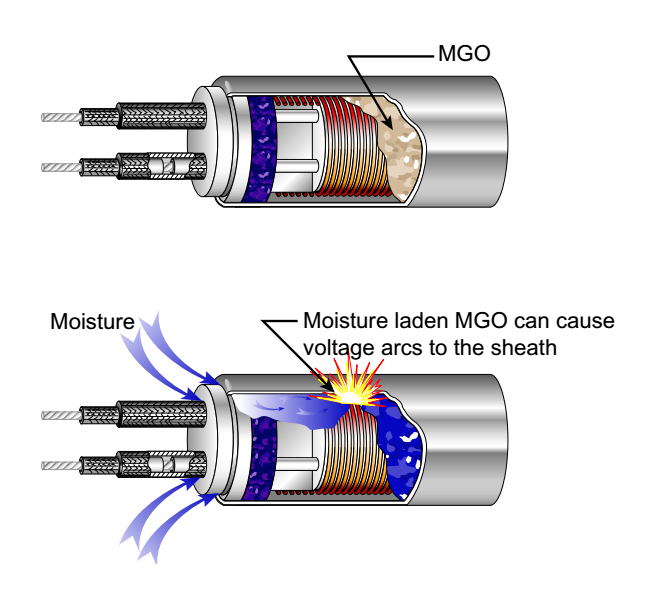

Understanding the ProblemFactories are hot, and in many cases very humid. This of course means there are potential problems with heating elements. The electric insulator in heaters, usually MGO (magnesium oxide), has a tendency over time to absorb moisture from the air. This occurs most often during down time on machines in damp environments or during long storage periods in stockrooms. When full voltage is applied to a moisture-laden heater, fuses blow, circuit breakers trip, and voltage arcs to the sheath and destroys the heater. |

Minimizing the Problem

If possible, it is best to store your heating elements in a humidity-controlled area. It is also advisable to spot-check elements before placing them into service.

Testing for the Problem

Moisture levels are measured by a Meg-ohm meter and can range from zero to infinity, which is generally thought to be greater than 5,000 Megohms as measured from the terminals to the sheath or casing.

Solving the Problem

Most manufacturers like to ship heaters at infinity. At a minimum, we recommend 10 Meg-ohms. At 10 Megs, the elements are about 99% dry. If excessive moisture is detected in an elements, you will want to take steps to remove it before applying power. This can be accomplished by placing the heaters in a 250° F oven. Most bake out times can be satisfied in 1 - 24 hours. Heaters with special end seals may take longer.

Another method for removing moisture is to run the heater at ½ voltage. This can work well but may take 12 - 24 hours, and Meg readings should always be taken before applying full voltage.

One of the relatively new devices on solid state controllers is a soft start feature. This is an excellent choice. Soft start applies varied voltage over time to slowly bring the heater up to temperature.

Another method for removing moisture is to run the heater at ½ voltage. This can work well but may take 12 - 24 hours, and Meg readings should always be taken before applying full voltage.

One of the relatively new devices on solid state controllers is a soft start feature. This is an excellent choice. Soft start applies varied voltage over time to slowly bring the heater up to temperature.

Proheat offers a variety of industrial heating products, including band heaters, cartridge heaters, strip heaters, tubular heaters, immersion heaters, and more. We are dedicated to providing excellence in distribution.