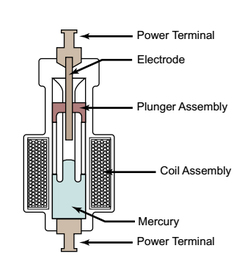

Mercury Displacement RelaysThe mercury displacement relay works by isolating the load terminals from each other. The “plunger assembly,” which includes a ceramic insulator, a magnetic sleeve and other related parts, floats on top of the mercury pool. When the coil is power causing a magnetic field, the plunger assembly is pulled down into the mercury pool, which is in turn displaced and moved up to make contact with the electrode, closing the circuit between the top and bottom load terminals. This relay must be mounted vertically and is good for millions of cycles. |

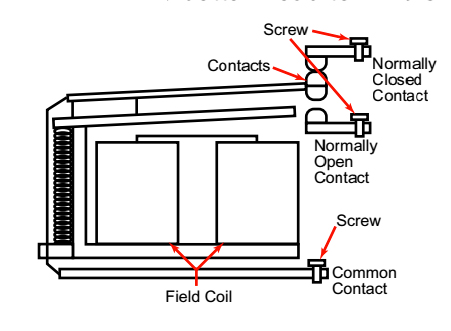

Electromechanical ContactorsThe electromechanical contractor, or relay, is an electrical and mechanical device with moving parts. When power is applied to the relay solenoid, contact closure is created through movement of the relays “common” contact. Because this contactor has moving parts, it is susceptible to vibration or mechanical failure. The closure of the contacts when powered results in contact failure through burning and pitting, which in fact is the primary reason for failure of an electromechanical relay. Electromechanical contactors provide a positive circuit break. This is important in many circuits. This contrasts with solid state devices which almost always have a small amount of leakage current flow. Electromechanical contactors can be mounted in almost any position and are much easier to install and service than many solid state switches. They are offered with normally open and normally closed contacts, with a very slight cost difference for both contacts. |

Solid State Switching DevicesSolid state switching devices have no moving parts and consequently no mechanical failures. Solid state switches are resistant to shock and vibration. The absence of moving parts also makes them noise-free (they produce no audible sounds). The most important factor affecting service life is its ambient operating temperature. Solid state devices are very durable if they are operated within tolerable ambient temperatures and are properly fused. Failure to dissipate the heat generated by any solid state component will quickly destroy it. Fusing (fast clearing I²t), location and heat sinking must be adequate. Because solid state relays can operate at much faster cycle time than electromechanical relays, they should be employed where extremely tight process control is required. Disadvantages of solid state relays include the inability to provide a positive circuit break and the failure mode when misapplied or subjected to overrated conditions. |

Silicon Controlled Rectifier (SCR)The SCR is a solid state switching device that can switch up to a 1200amp load. A correctly chosen SCR can reduce system cost by improving heater life process controllability. SCR power controllers typically accept two types of input signals: time proportioned (or on-off) and process signals (either 4-20mA or 1-4VDC) from any temperature control. SCRs accepting time proportioned (or on-off) signals are generally called “power contactors.” SCRs accepting process signals (4-20mA or 1-5VDC) are generally called “power controllers.” They control the power by the methods of firing, phase angle, and variable time base burst firing. The primary advantages of SCR power controllers are their flexible input options, lack of moving parts, long life, improved controllability and tremendous current handling capability. SCRs can improve system performance with increased heater life through the rapid switching an SCR provides. All SCRs require a proper heat sink and fast clearing fuses (2 millisecond). Location is also an important consideration. |

Proheat offers a variety of industrial heating products, including band heaters, cartridge heaters, strip heaters, tubular heaters, immersion heaters, and more. We are dedicated to providing excellence in distribution.