Kleentek

The Kleentek Advantage

|

Kleentek Electrostatic Oil Cleaning Systems have the unique ability to draw contaminants of all sizes out of machine oil, trapping them on the surface of the collector. This removal of all insoluble contaminants including tars and varnishes allows you to maximize your control for ultimate machine performance.

Traditional mechanical filters remove only large particles, while KLEENTEK electrostatic systems are particle size independent allowing submicronic particles as well as large contaminants to be removed from any non-conductive liquid. Only insoluble oil contaminants are extracted ; soluble additives that are present in the oil are not affected. Because this system is so effective in maintaining the cleanliness level of the oil, KLEENTEK eliminates the need for repeated oil changes and system downtime. KLEENTEK operates without supervision. |

Cost Justification Calculator

|

Click the button for a handy guide to show just how much money you can save by letting Kleentek do your dirty work!

Enter your current costs in the fields below, then click Calculate. This will generate a report, outlining your current costs, as well as projected costs after using a personalized Kleentek unit, specifically chosen based on your needs! How much money will you be saving next year? |

The Oil Problem Cure

|

Increases Profits

|

Increases Production

|

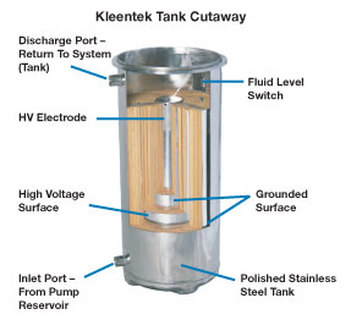

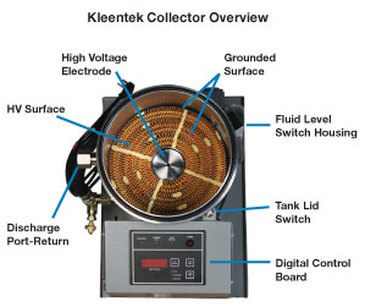

Unit Design

Each Kleentek unit has a flexible, modular design that allows it to be field-modified when mounting it to your system. Models are uniquely compact and are to be used as fixed, dedicated units. Kleentek is specifically designed to accommodate individual hydraulic and hydro-static systems. The collector is housed within a stainless steel chamber. Each collector is made of disposable cellulose fiber and is pleated to hold the greatest quantity of contaminants

|

Standard "DOC" Units

|

Standard Collectors

| ||||||||||||||||||||||||||||||||||||||||||||||||||||

How Kleentek Electrostatic Oil Cleaners Work

|

Advanced Technology. Unparalleled Performance.

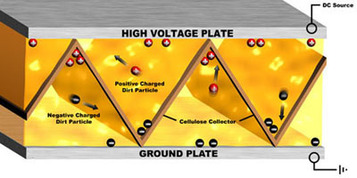

Kleentek utilizes a kidney-loop process that draws oil from a main reservoir and circulates it at very low velocity. The result: continual removal of contaminants from hydraulic fluid and lubricating oils. Using the principles of electrostatics to collect fluid contaminants, Kleentek's unique design utilizes gradient force, allowing it to take advantage of the natural charge that each contaminant contains. Contaminants with a positive charge are drawn toward a negative electrode within the system, while those with an inherent negative charge are drawn toward a grounded plate. As the fluid flows freely through the system, Kleentek removes contaminants, submicronic particles, dust, dirt and products of oil oxidation, including tars and varnishes. These contaminants are trapped in the collector for easy disposal. |

Customers Using Kleentek

|

|

|

|

Kleentek Specifications

|

Kleentek offers four models to meet the needs of virtually any hydraulic or oil lubricating application and performance requirement including:

|

Each unit has a flexible, modular design that allows it to be field-modified when mounting it to your system. Models are uniquely compact and are used as fixed, dedicated units. Kleentek units are specifically designed to accommodate individual hydraulic and hydro-static systems. Pumps are optional.

The collector, or filter, is housed within a stainless steel chamber and is made of disposable cellulose fiber. Each collector is pleated and features high-capacity contaminant collection. Kleentek systems provide continual operation from 2,000 to 10,000 hours of use dependant upon application.

Unit capacity may vary depending upon application. Performance specifications based upon units with pump options and oil at 140°F (60°C) or less. Standard power supply for all units is 120/1/60.

The collector, or filter, is housed within a stainless steel chamber and is made of disposable cellulose fiber. Each collector is pleated and features high-capacity contaminant collection. Kleentek systems provide continual operation from 2,000 to 10,000 hours of use dependant upon application.

Unit capacity may vary depending upon application. Performance specifications based upon units with pump options and oil at 140°F (60°C) or less. Standard power supply for all units is 120/1/60.

ProductsHeaters Sensors Temp. Controls Controls & Relays Hot Runners Heat Trace Cold Weather Wire Accessories Insulation Pressure Relief Slide Products |

ServicesCredit Application Order Tracking Delivery Programs Stocking Programs R.M.A. Request Catalog Request Custom Quick |

CompanyAbout Testimonials Legal & Copyright Blog |

SupportContact Account Managers FAQ Technical Information Instructional Videos Helpful Links Downloads Line Card |

Popular ProductsChromalox Heaters Watlow Heaters Watlow EZ-ZONE® Watlow F4T MDI Hot RunnerProheat is an authorized distributor of Chromalox and Watlow heater products. Band Heaters Cartridge Heaters Strip Heaters Tubular Heaters Immersion Heaters Hot Runner Nozzles Hot Runner Systems Hot Runner Controllers |

© Proheat, Inc.