Flexible Insulation Blankets & Covers

Benefits

Removable Insulation Systems benefit Proheat customers by reducing energy costs, safeguarding employees, maintaining consistent product temperatures, and providing noise reduction. As the market increases and evolves, we are committed to seeking after the latest technologies and advancements to provide our customers with superior quality insulation products and services.

Our flexible, reusable and removable insulation products including blankets, covers and enclosures are customized for each application, and are designed for easy removal and re-installation with no special tools. We use only the top performing high temperature textiles in the manufacturing of our insulation blankets and covers, all of which are asbestos free and environmentally safe.

Insulation blankets and covers can be used in a number of different applications with a wide range of performance features and offer the following:

Insulation blankets and covers can be used in a number of different applications with a wide range of performance features and offer the following:

- Reduced energy costs

- Temperature maintenance

- Improved employee safety

- Noise reduction

- Protection of valuable equipment by limiting exposure to harsh environments

|

Independent studies have shown that insulation provides the single greatest “payback” with the least amount of capital investment. Typical time to recoup insulation cost is three to six months based on the following figures: operating machines 24 hours per day, five days per week paying $.08 per kWh. If you run a continuous operation or pay more for your energy, the payback period is even less.

Our insulation blankets for barrels, dies and other plastics equipment can:

|

Increased Safety

Our component insulation lowers exposed surface temperatures, helping to reduce the chance of accidental burns. Our insulation blankets also create a noticeable difference in ambient air temperatures during the hot summer months.

Cost Savings Case Study

Overview

Decreased energy expenses and a reduction in labor costs are associated equipment insulated with removable insulation blankets. The custom insulation jackets are installed on valves, flanges, pipes, gas turbines, steam turbines and instrument panels. Because the insulation is removable labor costs are reduced because the equipment follows a routine maintenance schedule. When the insulation is removed very little downtime is realized because the removable insulation is replaceable quickly and efficiently. To ensure the equipment is re-insulated properly after a maintenance cycle owners, plant managers and plant engineers should purchase removable insulation blankets for those valves and flanges and other frequently maintained equipment instead of traditional insulation. Due to the cost of energy and labor the investment will quickly contribute to the company’s bottom line.

Energy Cost Savings

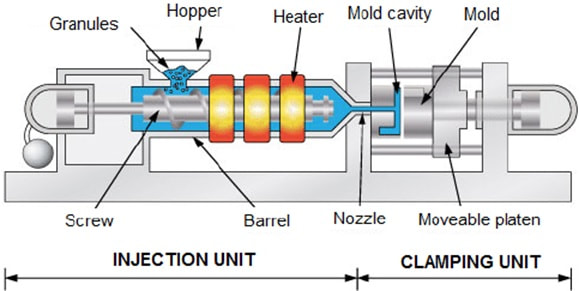

Injection molders, plastic extruders, refineries, chemical plants and energy plants are some of the most common customers purchasing removable insulation blankets today. Thermal energy is harnessed and used to operate the facility. Plants understand that insulation blanket or jackets reduce excess heat loss. The expense to have custom replaceable insulation installed literally pays for itself by reducing energy costs to a commercial facility. Its clear customizable removable insulation blankets or jackets save money by reducing heat loss.

This case study comparing removable blankets versus traditional insulation showed a $69,000 savings in cost after the very first maintenance cycle. The return on investment (ROI) on purchasing removable insulation blankets is rapid. Often the ROI is realized before the installation of the new removable insulation is complete. Energy efficiencies of 95 percent were achieved on surfaces that were 600deg when the removable insulation was properly installed in commercial facilities.

Decreased energy expenses and a reduction in labor costs are associated equipment insulated with removable insulation blankets. The custom insulation jackets are installed on valves, flanges, pipes, gas turbines, steam turbines and instrument panels. Because the insulation is removable labor costs are reduced because the equipment follows a routine maintenance schedule. When the insulation is removed very little downtime is realized because the removable insulation is replaceable quickly and efficiently. To ensure the equipment is re-insulated properly after a maintenance cycle owners, plant managers and plant engineers should purchase removable insulation blankets for those valves and flanges and other frequently maintained equipment instead of traditional insulation. Due to the cost of energy and labor the investment will quickly contribute to the company’s bottom line.

Energy Cost Savings

Injection molders, plastic extruders, refineries, chemical plants and energy plants are some of the most common customers purchasing removable insulation blankets today. Thermal energy is harnessed and used to operate the facility. Plants understand that insulation blanket or jackets reduce excess heat loss. The expense to have custom replaceable insulation installed literally pays for itself by reducing energy costs to a commercial facility. Its clear customizable removable insulation blankets or jackets save money by reducing heat loss.

This case study comparing removable blankets versus traditional insulation showed a $69,000 savings in cost after the very first maintenance cycle. The return on investment (ROI) on purchasing removable insulation blankets is rapid. Often the ROI is realized before the installation of the new removable insulation is complete. Energy efficiencies of 95 percent were achieved on surfaces that were 600deg when the removable insulation was properly installed in commercial facilities.

Contact Proheat

For more information on how to purchase our Flexible Insulation Blankets & Covers, contact Proheat today. A dedicated sales representative will be more than happy to guide you through the process. Thank you!

ProductsHeaters Sensors Temp. Controls Controls & Relays Hot Runners Heat Trace Cold Weather Wire Accessories Insulation Pressure Relief Slide Products |

ServicesCredit Application Order Tracking Delivery Programs Stocking Programs R.M.A. Request Catalog Request Custom Quick |

CompanyAbout Testimonials Legal & Copyright Blog |

SupportContact Account Managers FAQ Technical Information Instructional Videos Helpful Links Downloads Line Card |

Popular ProductsChromalox Heaters Watlow Heaters Watlow EZ-ZONE® Watlow F4T MDI Hot RunnerProheat is an authorized distributor of Chromalox and Watlow heater products. Band Heaters Cartridge Heaters Strip Heaters Tubular Heaters Immersion Heaters Hot Runner Nozzles Hot Runner Systems Hot Runner Controllers |

© Proheat, Inc.