← Band Heaters | Ceramic Band Heaters

Ceramic Band Heaters

Advantages of Ceramic Bands

|

Other types of band heaters are primarily conductive, requiring an intimate fit with components being heated. Grooves or other surface irregularities form voids under the bands, resulting in hot spots and premature heater failure.

Ceramic bands are recommended here because efficient heat transfer is not affected by irregular surfaces or loose fit. At higher watt densities they can be used in wider increments than other heaters. This means you can reduce the number of bands used and simplify wiring. |

|

Ultra Thin Ceramic Band Heaters

|

3/8" thick, , 3/16" thermal insulation, up to 65 watts/sq. in.

Proheat’s high performance ceramic heater band for processing high temperature engineering resins. "Ultra-Thin" heater bands have the same basic construction as our standard ceramic heaters except they are much thinner and have a high ratio of thermal to electrical insulation. The thin ceramic insulation’ used results in a lower mass construction, which improves response to control and minimizes temperature lag and overshoot. The backside thermal insulation is highly efficient and results in minimal heat loss and lower sheath temperature. The "Ultra-Thin" has averaged 100 deg. F lower sheath temperature when tested against other high temperature heaters at 600 deg. F cylinder temperatures. The "Ultra-Thin" without thermal insulation and with a perforated sheath is ideally suited for air cooled systems. "Ultra-Thin" ceramic band heaters are constructed of all high temperature materials. The heater element itself is computer designed for maximum wire size which results in a long service life. Developed primarily for high temperature, high watt density plastic processing machinery, this premium performance heater can be used in many other applications. Specifications

Options

|

Special Note

These are completely flexible radiant heaters. Heavy clamping pressures are not required regardless of heater size. No need for hinged, two piece, or expandable designs associated with mineral insulated (MI), mica or other conduction type heaters.

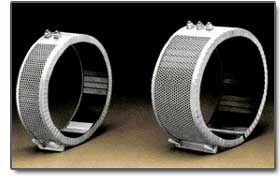

Air-Cooled Ceramic Band Heaters

|

Proheat's new, super-efficient and economical air cooled ceramic heater bands are designed for use on extrusion machinery or on any heat/cool operation.

Proheat’s new heater bands feature 63% open perforated metal sheath, which assures maximum surface area exposure. They also provide the user with a more economical operation, via a rapid heat-up and cool-down feature. Their "Black Star" coating further increases efficiency. Advantages of air cooled vs. Liquid cooled operation include: lower cost, replaceable heaters, low maintenance, no leak problems, and close temperature control. Proheat’s new air cooled ceramic heater bands are available in various sizes to either accommodate new designs or to replace less efficient, more expensive cast aluminum heaters. Proheat also offers a full line of custom and standard heaters and controls. Specifications

Options

|

Special Note

Terminal boxes and stud terminals are normally located 180 degrees opposite the gap.

ProductsHeaters Sensors Temp. Controls Controls & Relays Hot Runners Heat Trace Cold Weather Wire Accessories Insulation Pressure Relief Slide Products |

ServicesCredit Application Order Tracking Delivery Programs Stocking Programs R.M.A. Request Catalog Request Custom Quick |

CompanyAbout Testimonials Legal & Copyright Blog |

SupportContact Account Managers FAQ Technical Information Instructional Videos Helpful Links Downloads Line Card |

Popular ProductsChromalox Heaters Watlow Heaters Watlow EZ-ZONE® Watlow F4T MDI Hot RunnerProheat is an authorized distributor of Chromalox and Watlow heater products. Band Heaters Cartridge Heaters Strip Heaters Tubular Heaters Immersion Heaters Hot Runner Nozzles Hot Runner Systems Hot Runner Controllers |

© Proheat, Inc.